What Are Hospital Wristbands Made Of?

Introduction: Why Wristband Material Matters in Hospitals

Hospital wristbands play a crucial role beyond identification – they are essential for patient safety, medical accuracy, and streamlining hospital operations.

The composition of wristband materials directly affects comfort, durability, sterilization resistance, and barcode or print clarity—all critical issues for patient use. We investigated the top hospital wristband manufacturers worldwide, provided a comparative overview of the most common hospital wristband materials, and evaluated the pros and cons of different brands for hospitals and medical supplies distributors.

1. Main Types of Hospital Wristband Materials

1.1 Plastic Wristbands (Poly Materials)

Plastic wristbands are a hospital essential, offering cost-effective patient identification with durability and compatibility for various printing methods. However, different plastic sub-materials offer distinct advantages and limitations depending on their chemical makeup and physical properties. Here’s how PP(Polypropylene), Polyester, PVC, and Vinyl differ—and what that means for the healthcare industry and distributors.

🔹 1. Polypropylene (PP)

Material Characteristics:

Lightweight, semi-rigid thermoplastic

Supports direct thermal printing (no ribbon needed)

Inexpensive and mass-producible

For Hospitals:

Ideal for short-term use (outpatient, health checkups, day surgery)

Simplifies hospital workflows with quick, direct printing

No need for thermal ribbons — lowers equipment and supply costs

For Distributors:

Low-cost, high-volume product

Fast-moving inventory suitable for public hospitals and clinics

Competitive option for bidding on government or bulk orders

🔹 2. Polyester

Material Characteristics:

Durable, tear-resistant synthetic fiber

Compatible with thermal transfer printing

Maintains print quality over time

For Hospitals:

Suitable for longer hospital stays

Highly durable for departments with frequent hand hygiene or disinfectants (e.g., ICU, surgical wards)

Supports printing of barcodes and QR codes for digital patient tracking

For Distributors:

Mid- to high-end product segment

Ideal for offering bundled solutions (wristbands + printer + ribbon)

Preferred by hospitals using advanced identification systems

🔹 3. PVC (Polyvinyl Chloride)

Material Characteristics:

Rigid yet flexible plastic

Excellent resistance to liquids and disinfectants

Can be printed via thermal transfer or labeled manually

For Hospitals:

Suited for infection control units, emergency departments, and high-traffic wards

Maintains structure and readability even with frequent cleaning

Longer usable lifespan compared to PP

For Distributors:

Versatile product with wide hospital applicability

Works well in formal tenders and national hospital procurement lists

May require environmental compliance documentation (due to PVC’s chemical profile)

🔹 4. Vinyl (PVC-based Compound)

Material Characteristics:

Made from soft PVC with added plasticizers for flexibility

Often multi-layered for strength and comfort

Typically features snap closures for tamper resistance

For Hospitals:

Best choice for sensitive patient groups (maternity, pediatrics, psychiatric units)

Soft, flexible, and more comfortable for extended wear

Provides a secure fit with tamper-evident features

For Distributors:

Higher-end product with customization opportunities (e.g., pre-printed logos or colors)

Good profit margin with lower order volume

Strategic product for targeting private hospitals, specialty clinics, and international buyers

1.2 Tyvek Wristbands

Material: High-density polyethylene fibers (HDPE), branded by DuPont as Tyvek®

Tyvek wristbands are lightweight, paper-like bands that offer a simple and economical solution for short-term identification. Though they look like paper, their synthetic structure gives them unique properties that differentiate them from traditional materials.

Key Features of Tyvek in Wristbands:

Lightweight & breathable: Comfortable for short-term wear

Writable surface: Easy to mark manually with pens or markers

Single-use with adhesive closure: Helps prevent unauthorized reuse

Tamper-evident: Shows visible damage when removed or repositioned

What It Means for Hospitals

Benefits:

Ideal for temporary ID needs, such as emergency triage, visitors, or outpatient procedures

Cost-efficient, especially in high-volume, fast-paced environments

Customizable by hand (e.g., marking allergies, isolation status, triage level)

Limitations:

Not waterproof — may lose adhesion when wet

Easily torn — not suitable for patients who are physically active or require long stays

Not compatible with thermal or thermal transfer printers

Typical Hospital Applications:

Emergency rooms (ER)

Visitor or caregiver access control

Short-stay or outpatient clinics

Temporary patient classification (e.g., color-coded wristbands)

What It Means for Distributors

Strategic Advantages:

Low production cost → high margin for large orders

No need for printers or ribbons → simple logistics and lower entry barriers for clients

Strong B2B potential in volume-driven sectors (e.g., public hospitals, clinics, health camps)

Custom print options available (logos, text, color coding), increasing value-added service potential

Business Limitations:

Not suitable for high-end or long-term hospital use

Perceived as “disposable” → lower brand visibility unless customized

Vulnerable to environmental damage (moisture, tearing), limiting resale channels

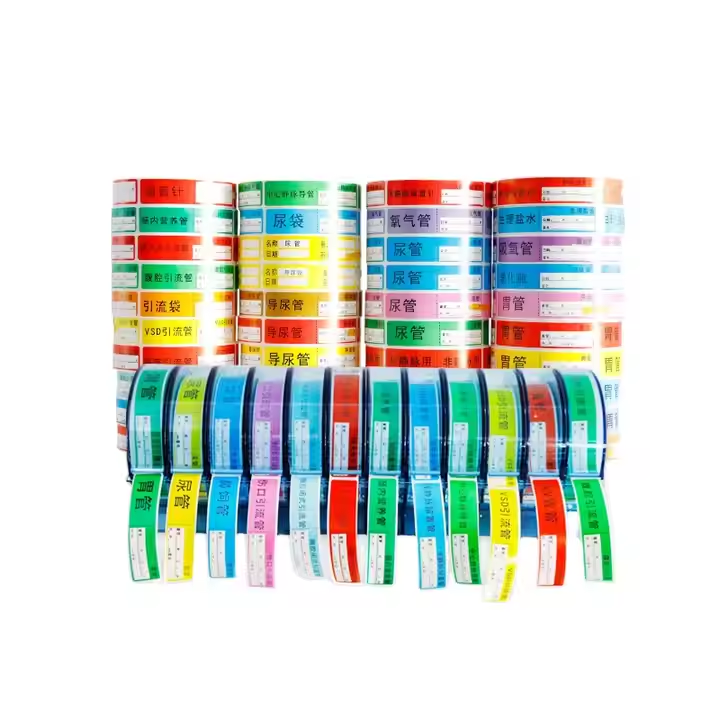

1.3 Nano-Silicon Wristbands — FTGO’s Proprietary Material

Material Structure: 82% Nano-silicon + Vinyl core, triple-layered construction

FTGO’s Nano-silicon wristbands are the result of over a decade of material innovation and testing, specifically designed for hospital use. These hospital ID wristbands are soft, hypoallergenic, antimicrobial, waterproof, and alcohol-resistant, ensuring maximum safety and comfort for patients of all ages.

![]()

Performance of Nano-silicon in Wristband Applications

Key Material Advantages:

Ultra-soft & breathable: Feels gentle on sensitive skin, ideal for long wear

Hypoallergenic & latex-free: Safe for patients with allergies or skin conditions

Antimicrobial surface: Inhibits bacterial growth for infection control

Resistant to alcohol and disinfectants: No fading or breakdown during sanitation

Waterproof and tear-resistant: Ideal for frequent washing and high-humidity environments

High print fidelity: Supports both thermal and thermal transfer printing with lasting clarity

For Hospitals: Clinical Advantages

FTGO’s Nano-silicon wristbands are engineered to improve both patient comfort and clinical efficiency:

Suitable For:

Neonatal & Pediatric Care: Soft enough for newborns, with secure yet gentle adhesion

ICU & Long-Term Care: Durable for extended stays and frequent sanitation

High-Hygiene Departments: Antimicrobial properties support infection control protocols

All Patient Groups: Available in adult, pediatric, and neonatal sizes

Wristband Options:

Thermal Wristbands: For fast, direct-to-print workflows

Thermal Transfer Wristbands: For long-lasting print durability

Write-on Wristbands: Ideal for temporary or mobile clinic use

Snap Closure Styles: Tamper-evident security for high-risk units

Self-Adhesive Styles: Simple application for all care levels

Custom Sizes & Colors: Tailored identification for specialized departments or hospital branding

For Distributors: Commercial Value

FTGO’s Nano-silicon wristbands offer premium differentiation in a competitive market. Here’s why they’re a strategic product line:

Market Advantages:

High perceived value: Hospitals are willing to invest in comfort, safety, and compliance

Flexible offerings: Cater to all wristband use cases—short-term, long-term, and specialty care

OEM potential: Custom logos, sizes, closures, and colors allow for brand-specific solutions

Excellent profit margins: Premium pricing with consistent demand in pediatric and long-term care sectors

Compliance-ready: Latex-free, antimicrobial, and alcohol-resistant features meet strict regulatory requirements

Product Overview Table

| Feature | Nano-silicon Wristbands |

|---|---|

| Material Composition | 82% Nano-silicon, Vinyl core |

| Comfort | ★★★★★ Ultra-soft, breathable |

| Durability | ★★★★★ Tear, water, and chemical resistant |

| Skin Safety | Hypoallergenic, latex-free, antimicrobial |

| Printing Methods | Thermal / Thermal Transfer / Write-on |

| Closure Options | Snap / Adhesive |

| Patient Fit | Adult / Pediatric / Neonatal |

| Use Cases | ICU, Maternity, Pediatrics, Long-term, High-Hygiene Units |

| For Hospitals | Premium comfort & compliance-focused identification |

| For Distributors | High-end product line with OEM customization potential |

Strategic Positioning Summary

For Hospitals:

Choose Nano-silicon for sensitive patient care, long-term comfort, and high hygiene standards.

Suitable for newborns to seniors, across all care durations.

For Distributors:

Position as a premium, next-generation solution.

Perfect for private hospitals, specialty clinics, and international buyers demanding elevated care standards.

Offer complete bundles: wristbands + compatible printer + ribbon (for thermal transfer types).

1.4 Specialty Materials (for Niche Use)

Some hospitals use niche materials based on specific patient groups or clinical needs:

Foam wristbands: For extremely sensitive or tiny wrists (e.g., newborns)

Fabric/Nylon wristbands: For geriatric or rehabilitation patients needing long-term wear

These are not widely adopted and are typically used as part of customized wristband programs.

2. Brand Material Comparison: FTGO vs Zebra vs SATO vs PDC

| Brand | Main Material(s) | Key Features |

|---|---|---|

| FTGO | Nano-silicon + Vinyl | ✅ Triple-layer design ✅ Antimicrobial & alcohol-resistant ✅ Ultra-soft & durable ✅ Ideal for sensitive skin and long-term care |

| Zebra | Polypropylene | ✅ Durable and waterproof ➖ Moderate comfort ➖ Less flexible than premium materials |

| SATO | Synthetic Polypropylene | ✅ Strong and printable ➖ Rigid structure ➖ Limited breathability over extended use |

| PDC | Polyester + Vinyl | ✅ Suitable for thermal transfer printing ➖ Average softness ➖ Balanced between durability and cost |

Key Insights for Hospitals:

FTGO offers maximum comfort, especially for sensitive patient groups such as newborns, pediatric patients, and long-term care units.

Zebra and SATO provide solid basic durability and are well-suited for general inpatient and outpatient care.

PDC delivers a mid-range solution, balancing comfort and thermal transfer compatibility.

Why Distributors Should Choose a High-Quality Hospital Wristband Manufacturer

For distributors, partnering with a high-quality hospital wristband manufacturer offers more than just superior products—it opens the door to long-term growth and client trust. Premium materials like FTGO’s nano-silicon and medical-grade vinyl ensure better patient comfort, hygiene compliance, and printing performance, which hospitals increasingly prioritize. By offering advanced wristband solutions, distributors can differentiate themselves in a competitive market, reduce return rates, and build stronger relationships with hospitals seeking reliability and innovation. High-quality wristbands also allow for OEM customization, private label opportunities, and expansion into premium healthcare markets. Choosing a top-tier manufacturer like FTGO ultimately enhances your brand reputation, increases customer satisfaction, and boosts recurring business.

Why Choose FTGO Hospital wristbands?

FTGO combines advanced nano-silicon with medical-grade vinyl to create a premium, hospital-grade wristband that significantly outperforms traditional materials in comfort and print longevity. Compared to other brands, FTGO wristbands:

Are softer and more skin-friendly, reducing discomfort during long-term wear.

Feature superior antimicrobial and alcohol-resistant properties.

Maintain print clarity for over one month—longer than any competing thermal or thermal transfer wristband on the market.

By contrast:

Zebra, SATO, and PDC thermal wristbands typically retain clear print for about two weeks before fading.

FTGO wristbands support both thermal and thermal transfer printing and are universally compatible with most leading hospital wristband printers.

⚠️ Compatibility Matters

Zebra’s Z-Band wristbands and PDC’s products are often locked to their own branded printers, limiting hospital flexibility.

FTGO wristbands work with most mainstream wristband printers, offering hospitals and distributors greater freedom and lower total cost of ownership.

🎯 Recommendation

If you’re a hospital currently using Zebra, SATO, or PDC wristbands—or a distributor of those brands—consider switching to FTGO for improved comfort, better hygiene compliance, and longer-lasting print performance.

We offer free samples for testing. Experience the FTGO difference today.

3. Material Recommendations by Hospital Scenario

| Scenario | Recommended Material | Why |

|---|---|---|

| Outpatient / ER | Tyvek | Affordable, fast deployment, suitable for < 2 days |

| Inpatient / Adult Units | Vinyl or Plastic | Durable, printable, waterproof |

| Neonatal / Maternity | Nano-silicon | Soft, anti-allergenic, safe for sensitive skin |

| ICU / Long-Term Stays | Nano-silicon | Long-term comfort, sweatproof, resistant to alcohol |

| Auxiliary ID Wristbands | Tyvek / Adhesive | Can carry extra visual cues for patient alerts or nursing instructions |

4. Why FTGO’s Nano-Silicon Wristbands Are Trusted Globally

FTGO’s hospital wristbands are engineered not only to perform but also to protect. Here’s what makes our material stand out:

Proprietary Nano-silicon blend: Engineered for comfort and performance

Triple-layered construction: Improves strength while maintaining flexibility

Antibacterial coating: Minimizes skin reactions and infection risk

Global compliance: Passed international skin-safety and material standards

High-definition printing compatibility: Supports barcode, patient name, and hospital info clearly and durably

5. From China to the World: The FTGO Wristband Story

FTGO’s journey began over a decade ago with traditional plastic wristbands. But through continuous material innovation and patient-focused research, we developed our signature Nano-silicon wristbands — now widely used across hospitals in China, and increasingly in Japan, Vietnam, Bangladesh, and the Philippines.Want to see how hospitals are using FTGO wristbands to improve patient comfort, safety, and operational efficiency?

👉 Click here to view our Hospital Wristband Case Studies

This advanced material was created specifically for the hospital environment and is trusted by medical staff across all departments and age groups. The overwhelming positive feedback from patients helped build trust with hospitals — and trust fuels global expansion.

At FTGO, we believe that something as small as a wristband can make a big difference in care quality. We hope to bring our premium Nano-silicon wristbands to hospitals all over the world — for safer, more comfortable patient identification.

6.Conclusion: Material = Safety, Comfort, and Trust

When it comes to hospital ID wristbands, choosing the right material isn’t just a procurement decision — it’s about patient comfort, clinical reliability, and brand trust.

FTGO continues to refine and improve wristband materials to meet the ever-changing demands of modern healthcare systems. Whether for long-term inpatient use, newborn identification, or high-turnover outpatient clinics, we offer reliable, durable, and skin-friendly solutions backed by years of experience and international success.

👉 Contact us today to request samples, discuss your hospital’s needs, or start a custom order.

Share this article

Follow us

A quick overview of the topics covered in this article.

- Introduction: Why Wristband Material Matters in Hospitals

- 1. Main Types of Hospital Wristband Materials

- 2. Brand Material Comparison: FTGO vs Zebra vs SATO vs PDC

- 3. Material Recommendations by Hospital Scenario

- 4. Why FTGO’s Nano-Silicon Wristbands Are Trusted Globally

- 5. From China to the World: The FTGO Wristband Story

- 6.Conclusion: Material = Safety, Comfort, and Trust